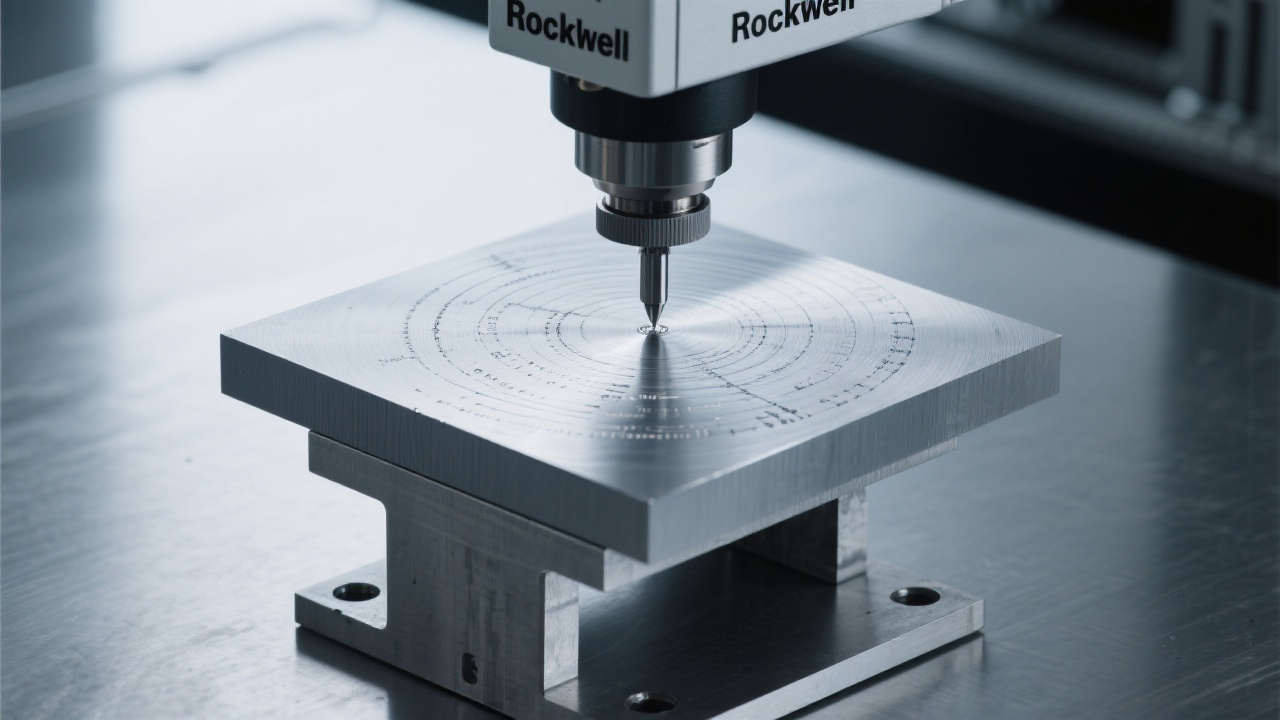

In precision materials testing, especially when dealing with micro-scale or brittle samples like ceramic coatings, thin metal foils, or microelectronic components, traditional hardness testers often fall short—delivering inconsistent results and requiring excessive manual calibration. That’s where the HVS-5A/10A/30A/50A series shines as a globally trusted export-grade solution.

The HVS series features a closed-loop load control system that ensures force application accuracy within ±0.5%, significantly reducing operator variability—a common pain point in labs using older models. Combined with a 10x digital microscope and 40x objective lens, it delivers clear, high-resolution images of indents even on samples as small as 0.1mm. This makes it ideal for quality assurance teams working with aerospace alloys, medical implants, or semiconductor materials.

“ISO 6507 and ASTM E384 compliance means every test is traceable, repeatable, and accepted across international markets.” — Quality Control Lead, European Materials Research Institute

These standards define everything from test force application to indentation measurement protocols. The HVS series automatically logs each step—from initial load to final reading—ensuring full audit trail capability. For manufacturers exporting to EU, US, or Middle East markets, this isn’t just a feature—it’s a requirement.

At a leading Japanese electronics manufacturer, the HVS-30A reduced testing time per batch by 40% while improving consistency across 30+ operators. Similarly, a German university research lab reported a 95% reduction in measurement discrepancies after switching from analog to digital systems.

Whether you're measuring diamond-like carbon (DLC) coatings on cutting tools or verifying hardness uniformity in titanium alloy sheets, the HVS series adapts seamlessly—with multiple scale conversions (HV, HK, HB) built-in for flexibility.

If your team struggles with unreliable data from fragile or tiny parts—if you’re tired of retesting due to poor visibility or inconsistent loads—you’re not alone. Many global clients have faced these exact challenges before finding their solution in the HVS series.

Have you experienced difficulties in measuring small or brittle samples? Share your story below—we’re listening.

Get a free demo, technical brochure, or live Q&A with our engineers today.

Explore HVS Series Features Now