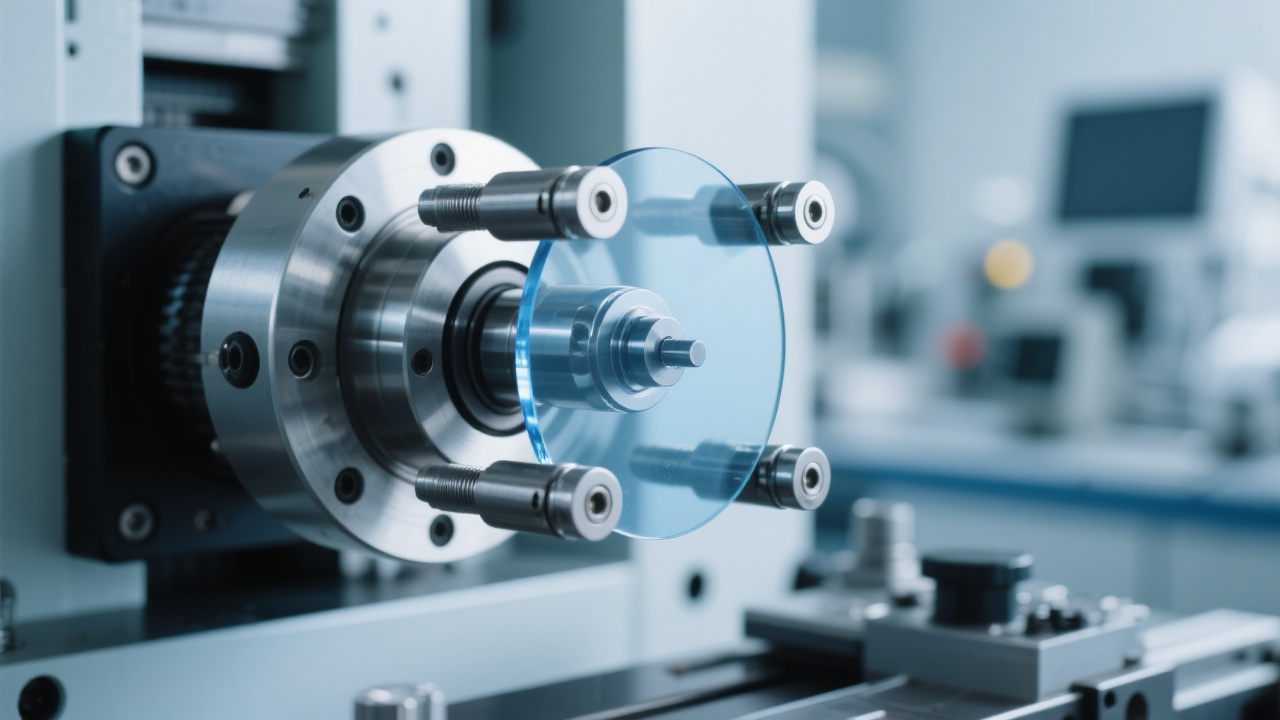

Laizhou Jincheng Industrial Equipment Co., Ltd. has recently introduced the digital imaging fully automatic Brinell hardness tester 12MHBS - 3000ZD. This article will delve into the key technical highlights of this advanced equipment, focusing on how the automatic turret design and digital image processing technology enhance the accuracy and efficiency of hardness testing.

The automatic turret design of the 12MHBS - 3000ZD is a significant innovation. It can automatically switch between different test heads, reducing manual operation time. In traditional hardness testing, manual head - switching may lead to an error rate of about 5% due to human factors. However, with the automatic turret, this error rate can be reduced to less than 1%. This not only improves the accuracy of test results but also increases the testing efficiency by approximately 30%.

The digital image processing technology is another core feature. It can capture and analyze the indentation images formed during the hardness test with high precision. By using advanced algorithms, it can accurately measure the size of the indentation, with a measurement accuracy error of less than 0.5%. This is crucial for ensuring the reliability of hardness test results, especially in scientific research and high - end manufacturing fields.

From the perspective of scientific research laboratories and high - end manufacturing, the operation process of the 12MHBS - 3000ZD is designed to be user - friendly. First, place the sample on the test platform. Then, select the appropriate test parameters through the control panel. The automatic turret will automatically switch to the corresponding test head according to the set parameters. After the test is completed, the digital image processing system will quickly analyze the indentation image and display the test result on the screen. Generally, a single test can be completed within 2 - 3 minutes, which is very efficient.

Regular maintenance is essential for ensuring the stability and measurement accuracy of the equipment. It is recommended to perform a simple cleaning and inspection of the test head and platform every week. A comprehensive calibration and maintenance should be carried out every 3 - 6 months. In case of common faults, such as inaccurate measurement results or abnormal operation of the automatic turret, the troubleshooting table provided by the manufacturer can be used for quick diagnosis and repair.

In different application scenarios, there are corresponding optimization skills. For example, in the aerospace manufacturing industry, where high - precision hardness testing is required, adjusting the test force and time according to the material properties can further improve the test accuracy. Through practical cases, it has been found that after using these optimization skills, the test accuracy can be improved by about 2 - 3%.

The content of this article is presented with the help of flowcharts, maintenance diagrams, and fault - troubleshooting tables, which greatly improves the clarity of information transmission and the user reading experience. In addition, an interactive Q&A and experience - sharing section will be set up to promote user participation, enhance user stickiness, and increase conversion rates.

Discover the Digital Imaging Fully Automatic Brinell Hardness Tester 12MHBS - 3000ZD Now!