When measuring the hardness of soft metals like pure aluminum and copper, you often face unique hurdles that can impact accuracy and repeatability. Are you struggling with selecting the correct load? Noticing unclear indentations? Or battling inconsistent data? This guide walks you through these critical issues, decoding the technical parameters you must consider for trustworthy Brinell hardness testing.

A common misconception is that applying a lower load yields higher precision in Brinell hardness testing of soft metals. In reality, using an inappropriate load can cause excessive indentation or insufficient penetration, skewing results significantly. For metals like pure aluminum and copper, a typical load range between 500 kgf and 750 kgf is often recommended in alignment with ISO 6506 standards (referenced below).

| Material | Recommended Load (kgf) | Typical Indenter Diameter (mm) |

|---|---|---|

| Pure Aluminum (Soft Alloy) | 500 - 750 | 10 |

| Copper | 500 - 750 | 10 |

| Brass | 500 - 1000 | 10 |

Manual hardness reading often introduces subjective error, especially with soft metals where indent clarity is limited. By using hardness testers with automatic digital displays, you can ensure precise value capture with minimal operator influence. Our featured Brinell hardness meter incorporates a high-resolution LCD menu system that guides you step-by-step through testing workflows, reducing mistakes and accelerating throughput.

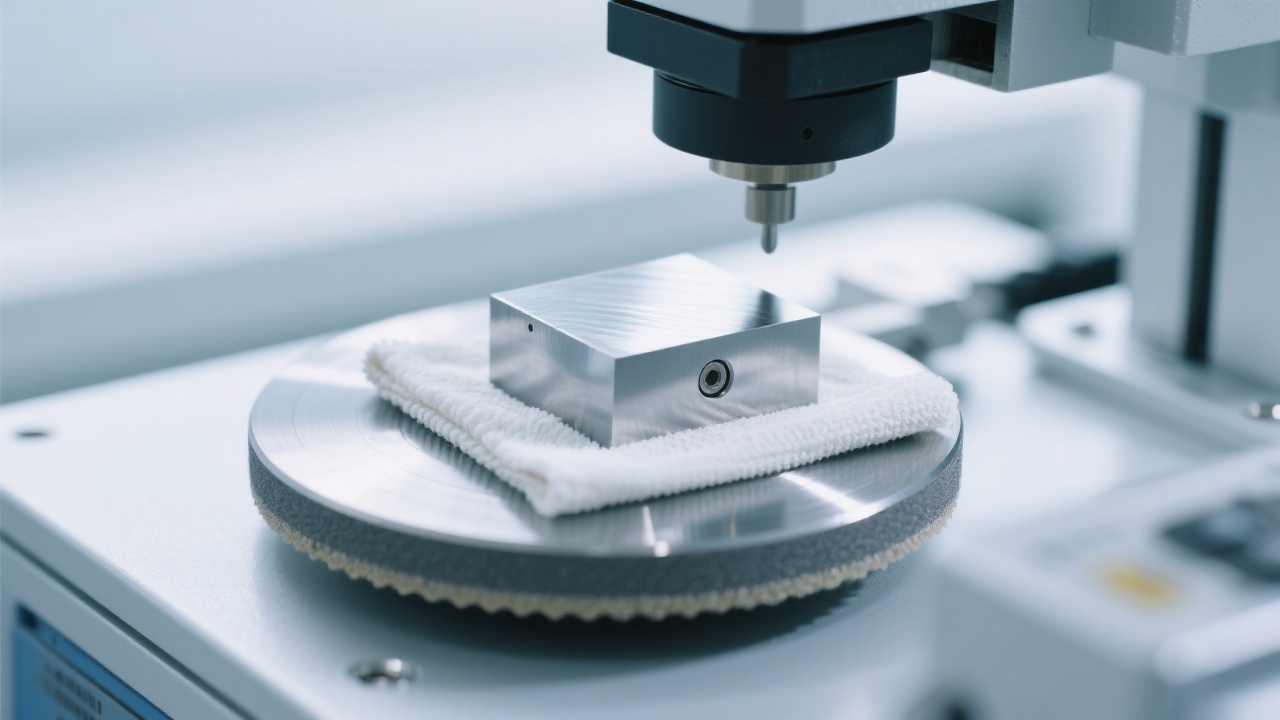

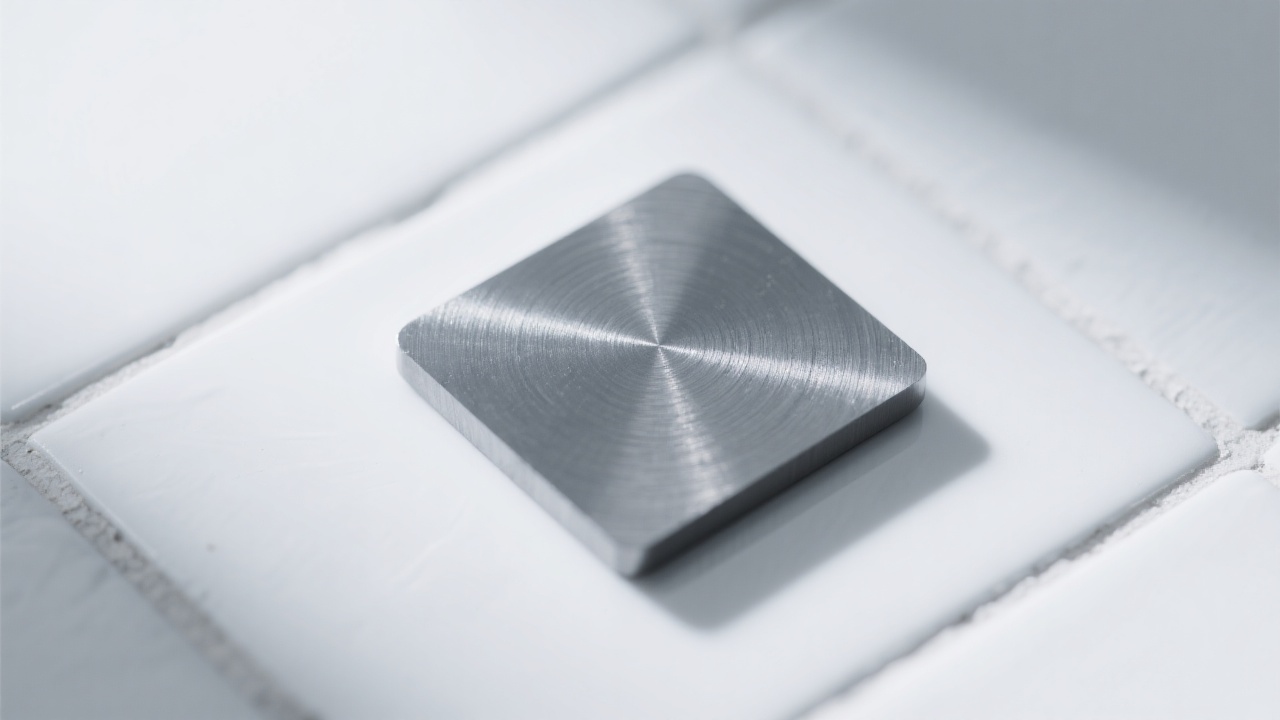

Clear, well-defined indentations are essential for accurate diameter measurement and hardness calculation. If your impressions appear blurred or irregular, verifying the cleanliness of the indenter ball and specimen surface is a must. Additionally, maintaining device calibration and applying consistent load dwell times—usually around 10 to 15 seconds for soft metals—helps preserve indentation quality.

Think of your hardness testing equipment as the foundation of your quality assurance process.

A structurally robust and durable machine withstands repetitive cycles in fast-paced metallurgical environments without loosening or drift. This mechanical integrity ensures test repeatability over years. For our Brinell hardness testers, rugged build quality and vibration-resistant frames safeguard test integrity even during high-frequency industrial use.

Reference: Compliance with ISO 6506-1:2014 confirms the standardized method for Brinell hardness testing, ensuring your measurements meet international quality benchmarks.

Depending on your production volume, material types, and lab capabilities, you should tailor your equipment setup accordingly. Automated load controls, user-friendly menu navigation, and quick calibration features enhance efficiency and reduce downtime. Consider environment-specific factors such as temperature, vibration, and workspace layout to select models designed to maintain accuracy under those conditions.

We recommend routinely reviewing inspection procedures and training personnel to leverage your hardness testing device’s automated capabilities fully. Doing so can improve reliability while decreasing operator-dependent variation.

Interactive question for you: What is your biggest challenge when testing soft metal hardness, and how are you currently addressing it?